|

Up

Up

Wright Engines

Wright Engines

And Propellers

(You are here.)

Down

Down

Need

to Need

to

find your

bearings?

Try

these

navigation aids:

If

this is your first

visit, please stop by:

Something

to share?

Please:

|

|

|

Available in Française, Español, Português, Deutsch, Россию,

中文,

日本, and others.

|

Wright

Engines – Taking advantage of a recent technological

advanced in "precipitate-hardening" aluminum, the Wright were among the

first to build internal combustion engines with aluminum cases, saving

hundreds of pounds without sacrificing power. Their engines, like their

airplanes, developed from finicky experimental devices to

commercial power plants renowned for their reliability. The power they delivered grew from 12

horsepower in 1903 to 75 by 1915.

|

A replica of the 1903 Wright engine

–

their first aircraft motor

–

with the crankcase exposed.

|

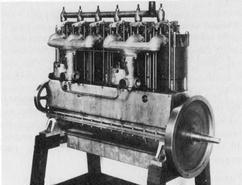

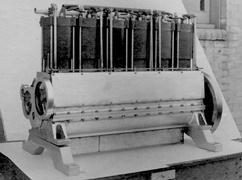

A late model Wright "6-60" six-cylinder engine, circa 1915. This was

one of the last engines produced by the Wight Company.

|

1903 Engine

– The gasoline engine that powered the first flights on December 17,

1903 delivered 12 hp when it was started, then dropped somewhat when the

motor heated up. It was built along a then-standard 4-4-4 design

– 4

cylinders, each 4 inches (10.2 cm) in diameter with a stroke of 4 inches

(10.2 cm). It had no spark plugs; each cylinder had electrical "points"

that sparked when they opened. This was called a "make-and-break"

ignition. The combined weight of the engine, water, and oil

was about 180 hundred pounds (81.6 kilograms).

|

The 1903 Wright engine was a "horizontal" engine

– the pistons moved

horizontally in the cylinders. There was no carburetor; the Wrights

dripped fuel into the intake at the top of the engine.

|

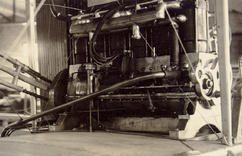

The 1903 Wright engine installed on the 1903 Wright Flyer. It was a

hot-running engine – the ignition chamber glowed a dull red after

the engine had been running for a few minutes, even with the

radiator connected.

|

1903

Propellers – The propellers that drove the 1903 Wright Flyer

through the air were the result of careful thought,

innovative mathematics, and combative arguing between Orville and

Wilbur. In the end, they agreed to treat their props as if they were

rotating wings. As such, the props had cambered blades to increase

thrust. After several experiments, the Wrights ended up with two

slow-turning (350 rpm) props 8.5 feet (2.6 meters) long. Each turned in a

different direction. This canceled out the sideways torque generated by

the spinning props.

|

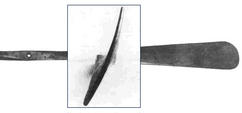

Two views of a 1903 Wright propeller. Note that the blade is cambered

–

it was designed as a wing

–

the camber produces lift in a horizontal

direction The design was remarkably efficient for its day,

converting 66% of the mechanical energy used to turn the props into

thrust.

|

The propellers mounted on the 1903 Flyer now on display at the

Smithsonian Air & Space Museum.

|

1904-1905 Engines

– Upon returning from Kitty Hawk, the Wrights built two horizontal engines.

One of these they mounted on their 1904 and 1905 Flyers. The other was

an experimental "bench" engine, used to test ideas to improve power,

reliability, and cooling. The Wrights would modify the experimental

engine to investigate an idea, and then transfer that modification to

the airplane engine if it worked. In this way, they eventually boosted

the output of their engines to 25 hp.

|

The 1904 experimental engine, also known as Wright Engine No. 3, is on

display at the

Dayton Engineer's Club in Dayton, Ohio.

|

The 1904-05 airplane engine

–

Wright Engine No. 2

–

mounted on the

1904 Flyer. It was later cannibalized for parts when Orville restored

the 1903 Flyer in 1916.

|

1905-1915 Bent-End Propellers

– In 1904, the Wrights noticed their propeller blades had a tendency

the flex at flying speed, altering the angle at which

they met the air. This in turn reduced thrust. At first Will and

Orv tried prevent this by increasing the width of the blade, but this

worked only partially. They next added "little jokers"

– triangular

extensions – to the trailing

edges of the blades so that when the prop flexed at speed, the blades

would be at the proper shape and pitch. This did the trick and evolved into

a distinctive shape known as the

Wright "bent-end" propeller.

|

Wright propellers evolved through several designs from 1904 to 1905. The

end result was the distinctive "bent-end" propeller that revolved

between 400 and 500 rpm and was 78% efficient. By comparison, modern

propellers are 82-83% efficient.

|

Bent-end propellers continued to be used on various Wright airplanes

that were manufactured through 1915. This particular prop was

designed to be used on the 1915 Model K, a large float plane the

Wrights built for the U.S. Navy.

|

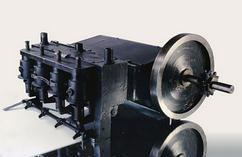

1906-1912

Vertical 4-Cylinder Engine – In 1906, the Wrights designed a

vertical 4-cylinder engine for use on their commercial airplanes. It had

individual cylinders that could be disassembled one at a time to make

maintenance easier. It also had spark plugs and a high-tension magneto to make the ignition system

simpler and more reliable. The first Wright "vertical 4" engine produced 28 horsepower,

but later improvements boosted this to nearly 40 hp. In later years, the

engine was referred to as the "Wright 4-40"

– 4 cylinders, 40 hp.

|

The Wright 4-40 also had a water pump (lower left) to increase cooling.

|

Wilbur lubricates a Wright vertical 4-cylinder engine in France in

1908. Although more powerful, the engine was actually slightly

lighter (180 lbs or 81.6 kg) than the Wrights' original horizontal-4

engines.

|

1911-1916

Vertical 6-Cylinder Engine –

As the need for more power and speed grew, the Wrights developed a

"straight six" engine

– six cylinders in a straight line.

This wasn't just a stretched 4-40, there were significant improvements

in the way the engine operated. This was the first of the Wright engines to employ standard

carburetion, giving it a range of speeds at which it could be operated.

Both the heads and the cylinders were water-cooled, so it ran much

cooler. And for the first time the exhaust was ported away from the engine (and

operator) through exhaust tubes. The enlarged and improved engine produced over 60

horsepower and was designated the "Wright 6-60."

|

The Wright 6-60 was also the first Wright engine in which both the

intake and exhaust valves were operated by a camshaft. Previous Wright

engines had automatic (spring-operated) intake valves.

|

The Wright 6-60 was first used on the Wright Model C, an upgraded

version of the Model B. It proved to be too much engine for the

airplane, pushing it too fast. But later Wright airplanes with

stronger aerodynamic airframes –

particularly Models F, G, and H – seemed to grow into the engine.

|

|

|