|

Up

Up

The 1901 Wright

The 1901 Wright

Wind Tunnel

(You are here.)

The

1903

Wright

Flyer I

The

1905

Wright

Flyer III

Need

to Need

to

find your

bearings?

Try

these

navigation aids:

If

this is your first

visit, please stop by:

Something

to share?

Please:

|

|

Available in Française, Español, Português, Deutsch, Россию,

中文,

日本, and others.

fter

the 1901 flying season at Kitty Hawk, the Wrights were seriously

discouraged. Neither of their gliders from 1900 or 1901 had worked

as anticipated or had produced sufficient lift. They had begun to

suspect that the data they were working with to design their

aircraft was incorrect. This data was gleaned from the experiments

of

Otto Lilienthal who, before his death in 1896, had designed 16

gliders and made thousands of glider flights, many more than any

pilot/scientist before or since. His unquestioned success gave

credence to his data. fter

the 1901 flying season at Kitty Hawk, the Wrights were seriously

discouraged. Neither of their gliders from 1900 or 1901 had worked

as anticipated or had produced sufficient lift. They had begun to

suspect that the data they were working with to design their

aircraft was incorrect. This data was gleaned from the experiments

of

Otto Lilienthal who, before his death in 1896, had designed 16

gliders and made thousands of glider flights, many more than any

pilot/scientist before or since. His unquestioned success gave

credence to his data.

Whatever the accuracy of Lilienthal's data,

the Wrights had come to a dead end. They simply did not know what to

do to improve the performance of their gliders. If they built a

third glider at this point, its design would be nothing more than

guesswork. And at their present pace, building and testing one

glider per year, it could be several lifetimes before they

discovered a workable design. Even then, they wouldn't know if it

was the best possible design.

They decided to discard Lilienthal's data and generate their own.

They built a wind tunnel, the second in America. (The first was

built by

Alfred Zahm.) Over the winter of 1901-1902, they tested over 200

wing shapes to find the most promising, then thoroughly investigated

about 45 shapes to determine the very best. To do this, they built

two instruments for their wind tunnel, one to measure lift and

another to measure the ratio of lift to drag.

When they compiled all their data, they were surprised to find

that Lilienthal had been correct. They, in fact, had been at naive

in the way they applied his data. Lilienthal investigated a single

wing shape that he used for all his gliders and his data was correct

for that shape only. The Wrights had presumed that even

though they used different shapes, Lilienthal's data for lift and

drag would be close enough. They were astonished to find just how

much difference in performance there was between wing shapes. Armed

with this new knowledge, they felt ready to get back in the air.

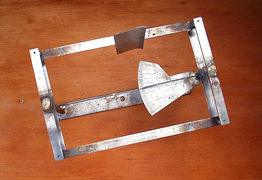

We built our tunnel and the balance instruments from the same

materials that the Wrights used, down to to the used hack saw blades

and spoke wire. But despite their crude construction, we found them

to be amazingly sensitive.

|

The Wrights' wind tunnel is little more than a wooden box with a tin

scoop on one side to direct and compress the air stream.

|

The air enters the tunnel through a two-stage "straightener"

designed to remove the roiling vortices that spin off the fan blade.

|

The air then travels down the length of the tunnel, allowing it to

settle into a uniform stream before it reaches the instrument.

|

There is a glass window directly over the instrument. Wilbur and

Orville stood on a box and looked down through this windows to read

the scales that measured lift and drag.

|

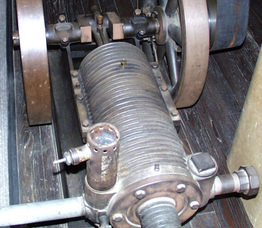

The fan blade was mounted on a grinding arbor, a tool that was

normally used to spin abrasive grinding wheels.

|

The arbor was spun by a leather belt that was turned by a series of

line shafts and pulleys.

|

The line shafts were turned by a one-cylinder engine that ran on

natural gas. This one engine, in fact, powered all the tools in the

Wrights' bicycle shop.

|

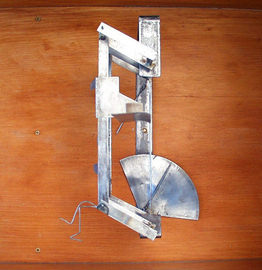

The first instrument the Wrights used they called the "lift

balance." It balances the lift generated by a wing shape against a

constant pressure on four metal plates or "fingers."

|

The moving parts of the balance pivot with almost no resistance.

The vertical parts – spoke wires – are ground to a point. The points

rest in small indentations in the horizontal parts – used hacksaw

blades.

|

Each balance has a scale or "quadrant" marked off in degrees. By

reading the scale and applying a little

trigonometry, the Wrights could predict how much lift or drag a

wing shape would produce.

|

On the lift balance the top set of "arms" are friction-fit to their

vertical shafts. This allow you to adjust the position of the top

arms in relation to those just below.

|

The lift balance also has an indicator to help calibrate and adjust

the instrument.

|

When the pointer is in the center of the "V," the balance is

properly adjusted.

|

When it's off-center, adjustment is needed.

|

To use the lift balance place it in the wind tunnel so the long

horizontal arms are perpendicular to the air stream. With the air

blowing, make sure the indicator is centered and the scale pointer

in on "0."

|

Mount the wing shape on the tab that protrudes from the long upper

arm. Adjust the shape so it's the proper "angle" of attack" to the

air stream.

|

Turn on the wind for a few moments and let the pointer come to a

rest over the scale. Turn off the wind. Note that the indicator is

no longer aligned with the "V."

|

Holding the pointer steady on the scale, move the top arms so the

indicator is centered. Turn on the wind and check that it remains

so. You may have to make several small adjustments to the top arms

until it does. When it stays centered, read the scale. The

sine of

the angle indicated is the coefficient of lift for that particular

wing shape.

|

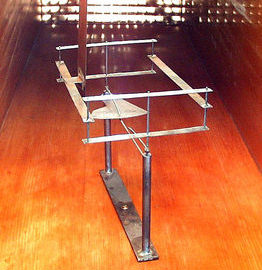

The second instrument the Wrights called the "drift balance."

Drift was their word for

what we now call drag. The

scale doesn't measure drag, however. It measures the ratio of lift

to drag. This is an extremely important number in aircraft design.

The higher the ratio – the more lift and the less drag – the more

efficient the wing shape.

|

Notice that each of these balances has two pointers, one of which points to nothing.

The Wrights added the second pointer so the pressure of the wind on

the sides of the pointers would cancel each other out and not

interfere with the measurement.

|

To use the drift balance, place it in the wind tunnel with the long

arms parallel to the air stream. Turn on the wind and make sure the

pointer remains on "0."

|

Mount a wing shape on one of the long arms so the chord is parallel

to the arm. Turn the balance so the wing is at the desired angle of

attack to the air stream.

|

Turn on the wind, let the pointer come to rest, and read the angle

on the scale. Add this angle to the angle of attack. The

tangent of

the resulting angle is the ratio of lift to drag.

|

To mount the airfoils on the balances, the Wrights soldered two

small brackets to the top surface of each foil, so close together

that the brackets were almost touching.

|

These brackets slip over the crossbars of the balances. The fit is

snug, but not so tight that the foils cannot be easily mounted and

dismounted.

|

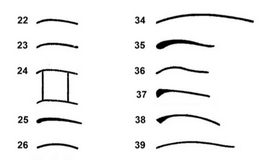

The Wrights made preliminary tests on over 200 wing shapes, then

thoroughly investigated 57 of the most promising. The foils are made

of sheet steel; thicker portions are built up with wax.

|

|

|